Our test lab validates products and materials using a wide variety of equipment. It also has a cleanliness unit to meet the quality requirements of your products.

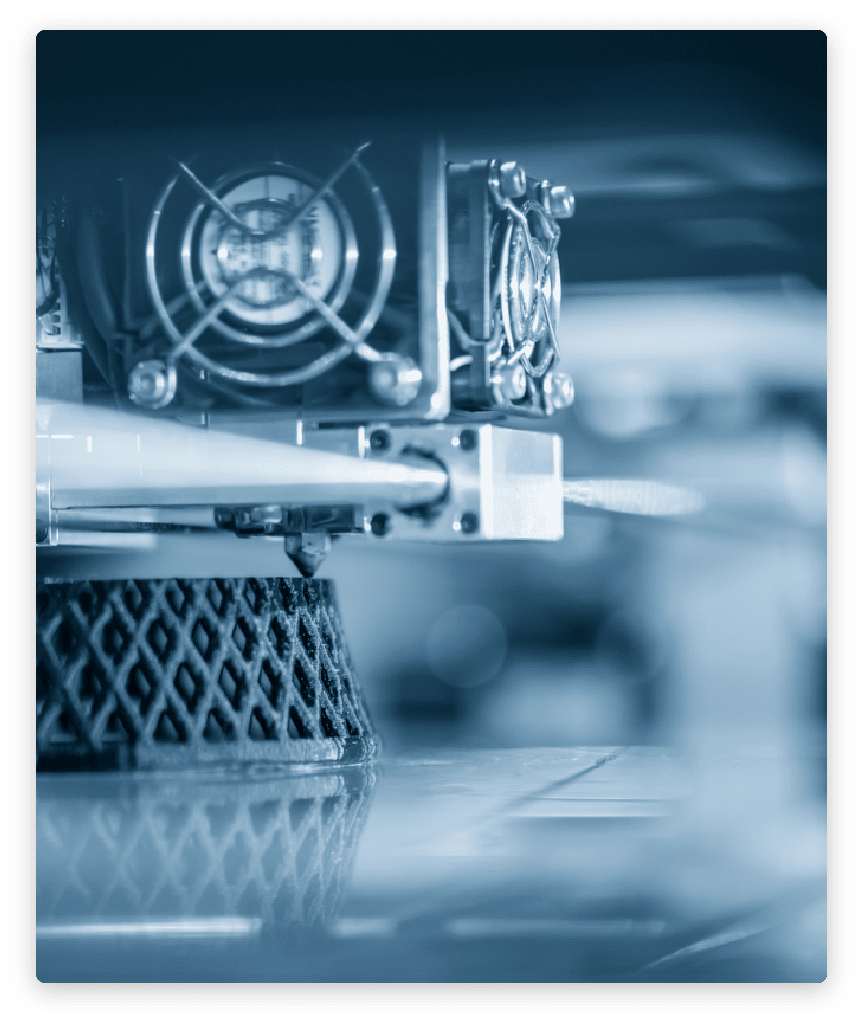

FAVI has always considered engineering a priority. Our Studies team will be a genuine partner in your development, putting forward ideas and suggestions to ensure optimum product performance as soon as it goes into series production.

Our production engineering department adapts our machinery to meet your needs. FAVI can meet your requirements for long production runs with automated production lines, but also offers flexible equipment better suited to short and medium runs.

Decarbonisation is a major challenge we all face for the future, which is why our Quality, Health, Safety, Environment and Energy policy forms an integral part of our corporate culture and development strategy.

A team of dedicated, devoted, autonomous and responsible men and women, here to serve you.

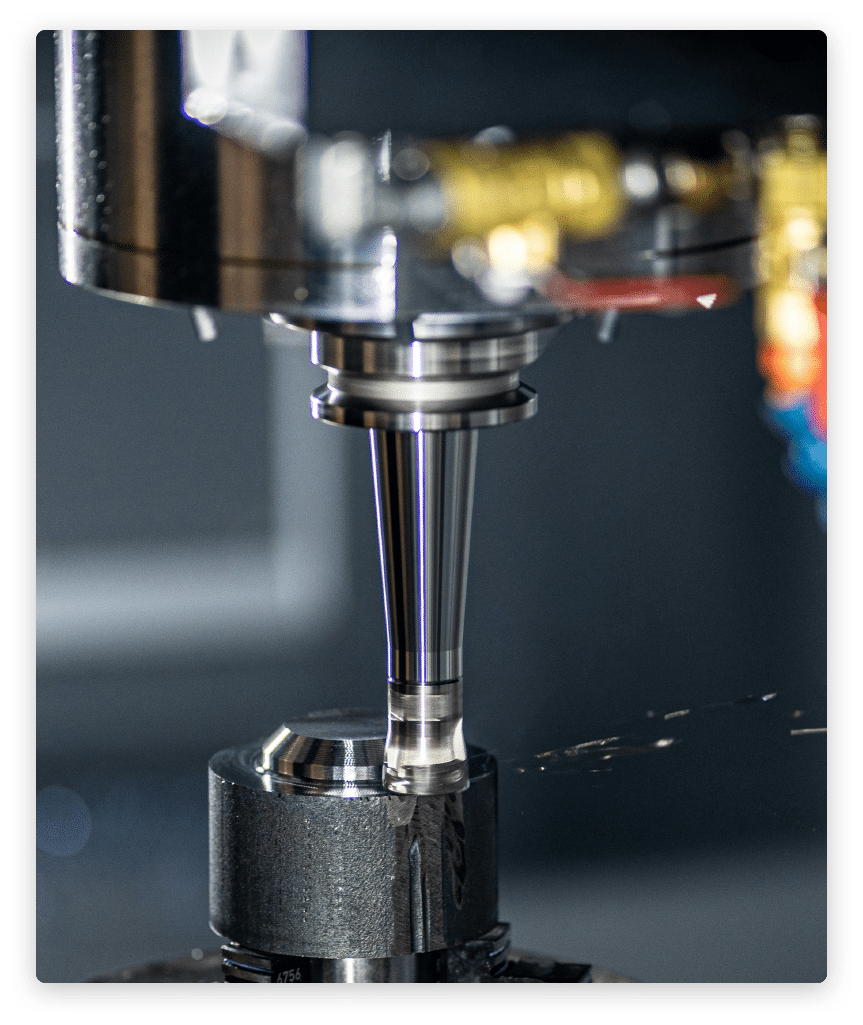

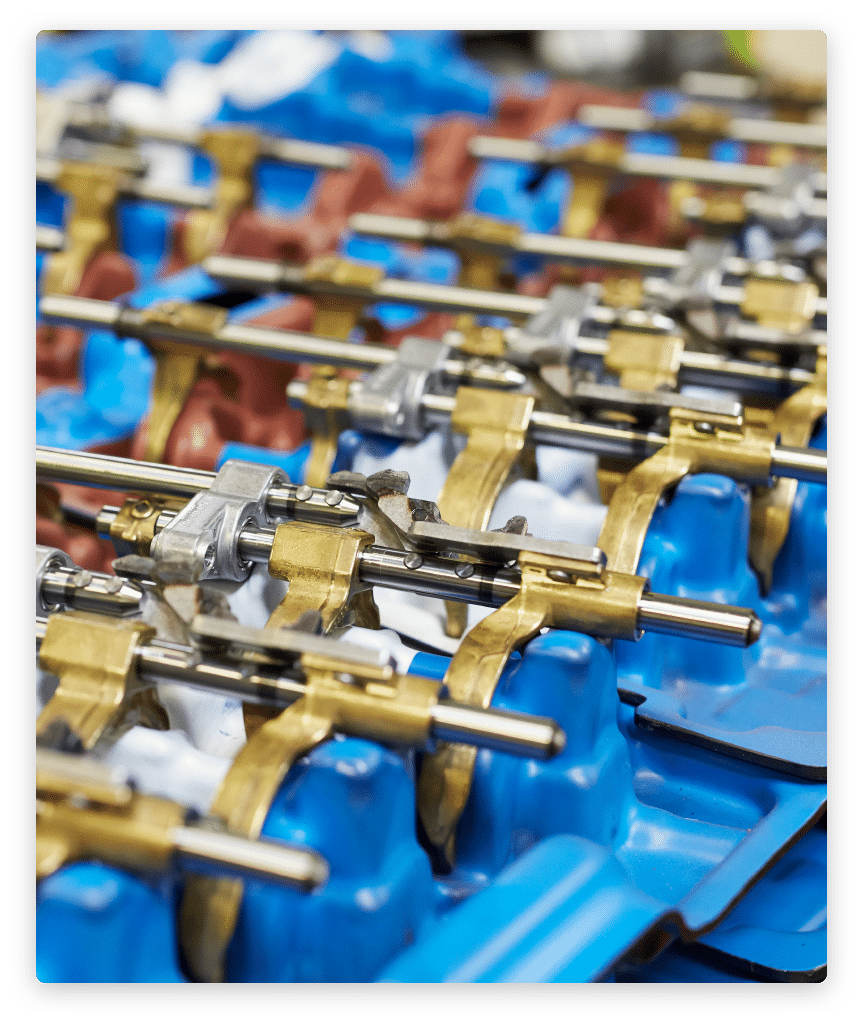

Our core business for over 67 years: pressure die casting. 60 years developing in-depth expertise in the choice and use of aluminium, brass and copper alloys to suit your project and meet your technical and economic requirements.

FAVI stands out for its commitment to quality and precision, expertly machining each and every part to ensure the delivery of reliable products. Over 100 CNC and turning machines for machining aluminum, brass, copper and steel.

FAVI stands out for its technical mastery in the assembly of complex solutions, using cutting-edge processes and integrating multiple components.

FAVI stands out as a provider of industrial subcontracting solutions, delivering tailored, efficient services to meet the diverse requirements of its partners in the industrial sector.

FAVI is a family firm based in Hallencourt in Northern France specialising in the development and production of machined and assembled technical solutions made from pressure die-cast aluminium, brass and copper. FAVI has a highly autonomous, innovative workforce able to provide the answers you need. It is also strongly committed to product quality, health and safety, and especially sustainable development.

Yes, FAVI undertakes to understand the specific needs of its customers and to offer tailored solutions to meet their particular requirements.

To discuss a potential partnership or get more information about the services FAVI can provide, you can contact our sales team via our website or using the contact details on the Contact page.

Yes, FAVI does offer engineering subcontracting services to help its customers optimise their manufacturing processes and achieve their objectives as effectively as possible.

FAVI is committed to adopting sustainable practices in its operations, keeping waste to a minimum, optimising the use of resources and favouring environmentally friendly production methods.

FAVI attaches great importance to the confidentiality of its customers’ projects. Strict protocols are in place to guarantee the security of sensitive information and the protection of intellectual property rights.

Yes, thanks to its technical expertise and its network of subcontractors, FAVI is able to support you through every stage from development to the series production of your products.

Thanks to its parent company Afica, Favi definitely has the capacity to design new alloys with specific properties, proving its expertise in the development of innovative materials.

With over 80% of our tooling designed, made and maintained in house, we are able to offer optimum levels of flexibility and responsiveness in our processes.

To guarantee the cleanliness of your product, we have a special cleanliness unit in our lab benefiting from cutting-edge expertise and specific production equipment to ensure high-quality washing.

Absolutely. We attach great importance to the success of your project. So, right from the start, we will set up a dedicated, multidisciplinary project team. This team will be carefully put together, with professionals with varied and complementary skills and expertise, in order to provide the best possible response for every aspect of your project. This approach guarantees comprehensive and effective management of the development process to be sure of achieving the objectives set.

©2024 – FAVI – Tous droits réservés – Un site Nord-Image