Alongside our engineering and industrial subcontracting services, our field of expertise also extends to a comprehensive range of industrial solutions encompassing, among others, aluminium, brass and copper pressure die casting, machining and assembly technologies.

FAVI can support you with the development and manufacturing of brass technical parts, aluminium solutions and copper cage rotors to meet the specific needs of multiple industrial sectors.

In addition, Favi is now expanding its offer to meet a growing demand from its customers, providing them with technical expertise (engineering department, lab) and offering comprehensive industrial subcontracting services.

By combining these different elements, Favi is helping to create innovative, competitive products and to shape the future of the industry.

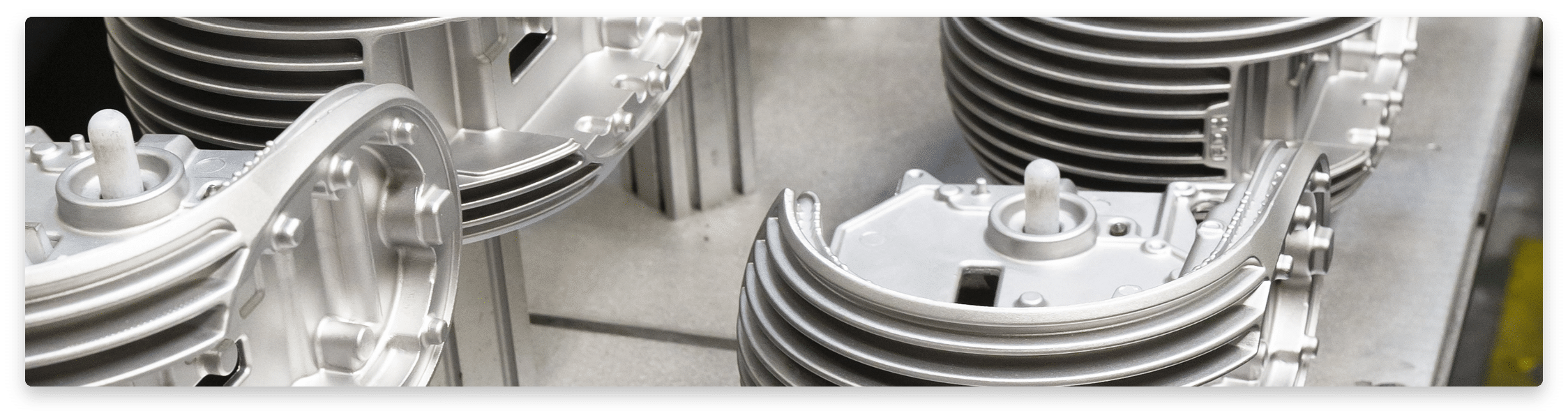

Favi is a prominent leading producer of aluminium technical solutions, offering a wide range of products designed to meet the specific needs of different sectors of industry.

Favi continually strives to produce the highest quality solutions using standard alloys, but it also has the capacity to develop special alloys in partnership with its parent company, Afica.

Currently, we offer a wide range of products specifically suited to the needs of various sectors, including agriculture, electricity, electronics, automotive and many others.

In most cases, these are not simply die-cast parts, but rather complex subassemblies whose production involves machining, assembly, washing and sometimes even surface treatment operations.

At Favi, we aim to put our technical expertise to work for the benefit of our customers, offering them innovative, quality solutions to meet their specific needs in key sectors.

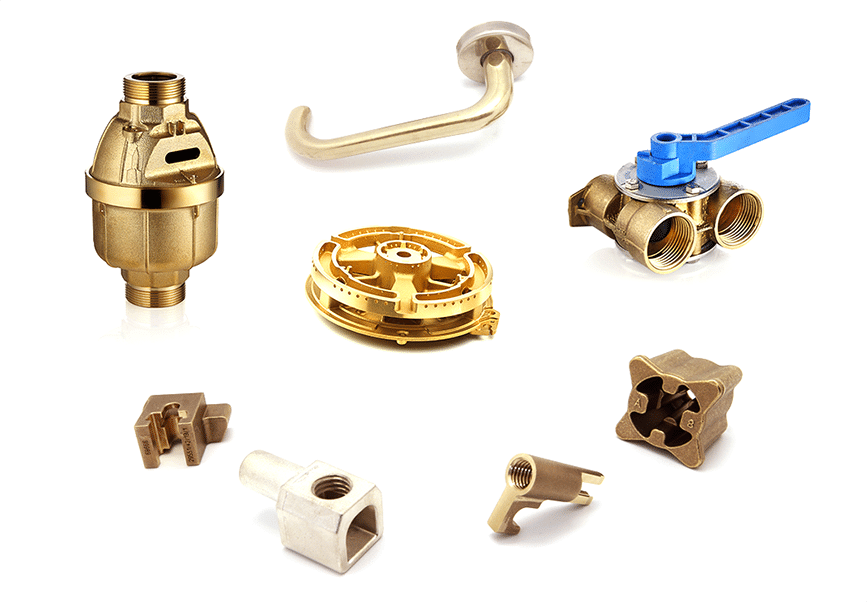

Favi has specialised in making brass technical parts since the company was founded in 1957. Our expertise in pressure die casting means we are able to produce precision technical parts weighing anything from 4 g to over 2 kg.

The combination of our production capacity and our unwavering commitment to quality makes us a preferred partner in multiple industries. In fields as varied as water meters, locksmithing, plumbing, aerospace, electrical equipment, to name but a few, we put our know-how to use producing reliable and often customised technical solutions.

To develop its different alloys, Favi can draw on the expertise of its parent company, Afica, which gives it a distinct advantage. AFICA offers a wide range of bespoke alloys, banishing standardisation in favour of custom developments fine-tuned to meet the needs of firms in a wide range of industries.

At Favi, we know how important it is to meet the specific requirements of each industry, and that is why we are committed to providing the highest quality parts, to guarantee the satisfaction of our most demanding customers.

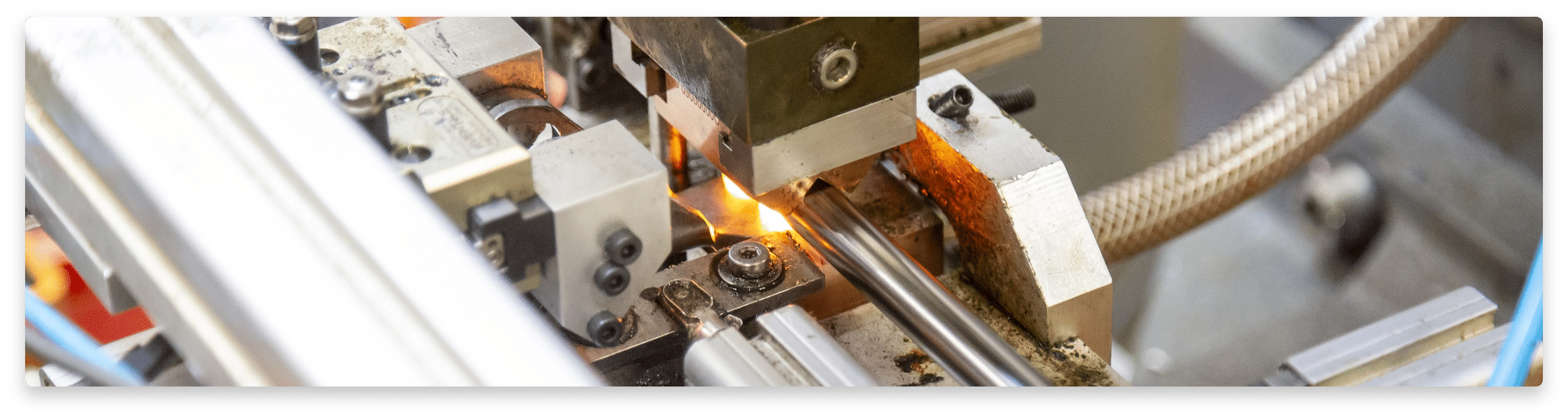

Favi is expanding its service offer to meet growing demand from its customers, now offering a comprehensive subcontracting service. We offer a diverse range of services, but most notably prototyping, machining and component assembly. Whether we are producing prototypes to validate new products, machining complex parts or assembling final components, we employ our cutting-edge know-how, skills and resources to meet the most demanding requirements.

Prototyping is a crucial stage in the product development process. At Favi, we understand the importance of producing quality prototypes quickly and efficiently. With our advanced manufacturing capabilities and team of experts, we are able to produce functional prototypes with a high degree of precision within a short space of time.

Precision machining is another essential aspect of our subcontracting services. Our modern machinery and skilled technicians mean we are able to machine a wide range of materials with a high degree of precision and an exceptional level of quality. Whether your need is for simple parts or complex components, we are equipped to meet all of our customers’ machining needs.

Finally, our expert assembly service completes our subcontracting offer, enabling our customers to benefit from turnkey solutions. Thanks to our expertise in project management and our constant attention to detail, we will assemble your components with precision and rigour to guarantee quality and reliability of your end products.

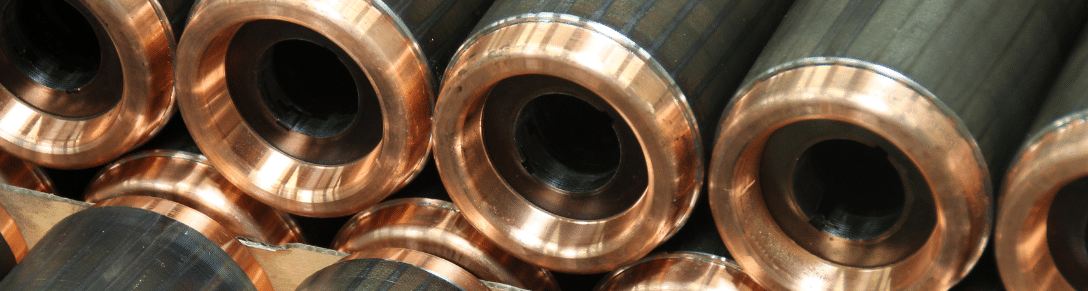

Favi is renowned for its ability to produce high quality copper rotors for industrial motors. The use of copper in our rotors offers significant advantages in terms of efficiency and performance, resulting in substantial energy savings and better overall motor efficiency. Thanks to its excellent electrical conductivity rating, the die-cast copper in the rotor leads to a remarkable increase in efficiency. Simply replacing an aluminium rotor with a copper rotor can generate an increase in efficiency of up to 4.3%. It can even reach 6.4% if the replacement of the rotor is accompanied by measures to optimise the motor. These efficiency gains translate into significant energy savings, which can only be a significant plus in view of the current issues around energy consumption.

In terms of investment, the motor now represents only 2.5% of the total cost over its life cycle. The savings made on electricity consumption thanks to the exceptional performance of copper make for a fast and tangible return on investment. Furthermore, the use of a copper rotor offers other notable advantages. In fact, for the same power output, a motor with a copper rotor will be smaller, lighter and cheaper to manufacture than a motor with an aluminium rotor. This improvement in the power-to-weight ratio contributes to better overall motor efficiency.

From an environmental point of view, changing to a copper rotor also considerably reduces CO2 emissions. By replacing the aluminium rotor with a copper one, the electrical consumption falls, leading to a reduction of about 3.8 tonnes of CO2 over the estimated lifespan of a 3 kW motor, based on 3,000 hours’ operating time per year for 15 years, in accordance with European standards. Finally, using copper also extends the life of the motor. By reducing the operating temperature by about 30°C, copper reduces the thermal stress on the asynchronous motor, which results in a longer lifespan and greater reliability.

To sum up, the copper rotors made by Favi represent a technological solution offering higher performance, substantial energy savings and undeniable environmental benefits, whilst also guaranteeing industrial motors and extended lifespan.