FAVI has been European leader in gearbox internal controls since 1979. The company is now expanding its offer with innovative, complete solutions for electric vehicles and soft mobility.

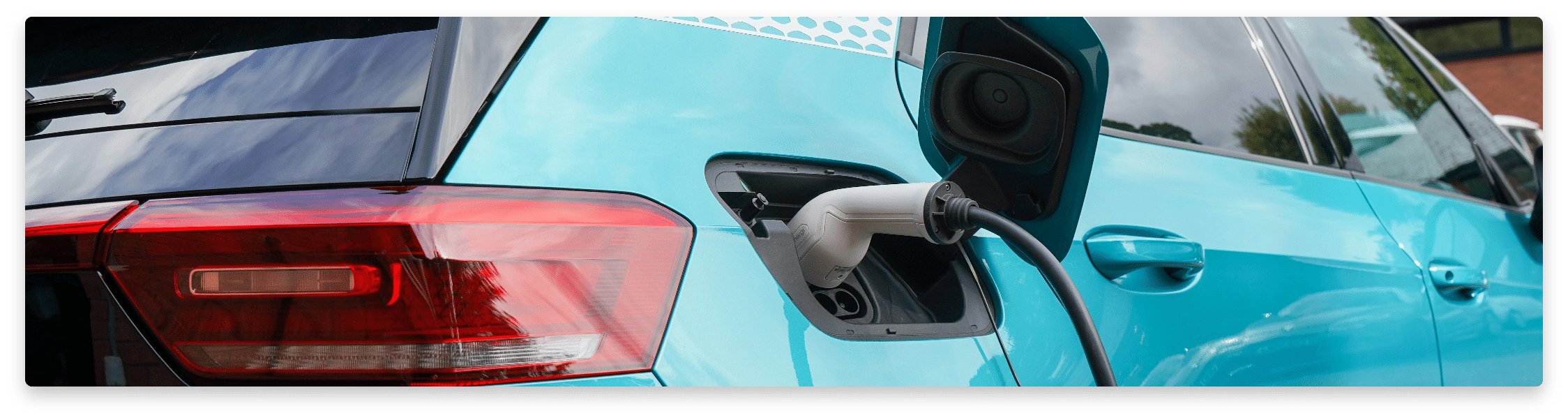

The future promises a revolution in the way we explore the world. The advances we are seeing are not just limited to the technology, but also encompass concepts like sustainability, flexibility and the reduction of our carbon footprint. Beyond its expertise in internal gearbox controls, FAVI is striving to implement an approach that takes account of all these factors by proposing innovative, complete solutions for electric vehicles and soft mobility.

FAVI offers a wide range of pressure die-cast copper alloy and aluminium components and subassemblies. These parts may require complex machining and assembly operations or surface treatment. FAVI attaches great importance to the quality perceived by its customers and implements advanced testing and inspection methods to guarantee their total satisfaction. But FAVI’s commitment is not just to the quality of its products. Out of a genuine concern for the environmental impact of its activities, the company is continually striving to minimise its ecological footprint by adopting sustainable production practices and investing in eco-friendly technologies.

By working closely with a variety of innovative and visionary companies in the soft mobility sector, FAVI is actively helping to shape a future where mobility will be synonymous with sustainability, practicality and efficiency. Thanks to the intelligent extension of its historic know-how in the automotive market to other applications, the company is now manufacturing innovative parts for the soft mobility sector.

Whether you make balance bikes, scooters, electric bikes or light quadricycles, FAVI can help you to develop drivetrains, chassis, frames and other technical components.

FAVI, contributing to reshoring the soft mobility industry in France and in Europe.

While FAVI is diversifying into new market segments, we remain attached to the automotive market, still a central part of our strategy. The automotive industry is in the midst of major changes as the electric revolution gets underway. Driven by an unwavering commitment to excellence and innovation, FAVI remains at the forefront of that revolution, ready to meet the forthcoming challenges and pave the way for a cleaner, brighter future for all.

The electric vehicle revolution relies on a series of innovative technologies, including thermal management and power electronics, which play a crucial role in optimising the performance and energy efficiency of electric vehicles. Thermal management is an essential discipline aimed at controlling the ideal operating temperatures of key components.

Thermal management technologies include liquid or air-cooling systems, thermally conductive materials and sophisticated control algorithms for dynamic temperature monitoring and regulation.

In this context and supported by multiphysics (heat transfer/fluid mechanics) and rheology software, FAVI develops innovative components based on its pressure die casting process. Thanks to the resources of its parent company Afica that it can draw upon, Favi is able to explore new frontiers in the development of innovative alloys which can help to maximise the benefits of thermal management. These components will considerably improve the thermal management of power electronics modules. By synergistically combining thermal management and power electronics, automotive manufacturers are managing to design more powerful, more reliable and more energy-efficient electric vehicles.

In addition, since 2002 FAVI has also offered copper cage rotors for your electric motors and drivetrains.

A FAVI rotor in an asynchronous motor also gives it a higher power-to-weight ratio, up to 4 kW per kg of motor. In the automotive industry, manufacturers are always looking to maximise power from the smallest possible motor, because reducing the vehicle weight in this way extends its range.

This range of products has been the company’s core business since 1979. Every day we deliver complete subassemblies to all the main European automotive manufacturers.

Our CuZn27 brass and our hypereutectic aluminium-silicon alloys give our products excellent wear resistance and allow us to offer customers high performance at low cost. In addition, these materials are entirely recyclable, making FAVI’s solutions ecologically virtuous.

FAVI aims to remain European leader in internal gearbox controls for ICE, hybrid and plug-in hybrid vehicles until 2035, and after that to conquer the global market. Internal control solutions are also being developed for the e-drivetrains and reducers in electric vehicles.

©2024 – FAVI – Tous droits réservés – Un site Nord-Image